Mystery box

In 2019, the Norwegian Petroleum Museum opened a new 3,500 square meter modern storage that will house memorabilia from the oil industry. Before 2019, the museum’s items were spread across several locations. Work is still underway to empty old warehouses and give the objects a place in their new home. From time to time, things appear that we know little about, including a mysterious box with numbered pieces of metal. What was its significance?

Upon further investigation, it turned out that the box came from Statoil. [REMOVE]Fotnote: Now Equinor The objects came from Alexander L. Kielland, the oil rig that capsized in the North Sea in 1980. The rig capsized after one of its five legs was torn off, a tragedy that claimed the lives of 123 men. The pieces of metal were central to the investigation of the accident, which concluded that the cause was a welding error.

In order to get more information about the mysterious objects, Bjørn Lian was invited to the storage in autumn 2022. Perhaps he could shed a light on the content of the box?

Bjørn Lian is a sivilingeniør and was employed by Statoil in the period 1975 -2005. He worked with materials technology and had worked on drawing up specifications, purchasing and quality control of steel. After the Kielland accident he was appointed as an expert and worked on assignments for the Commission of Inquiry, which worked to find the cause of the accident.

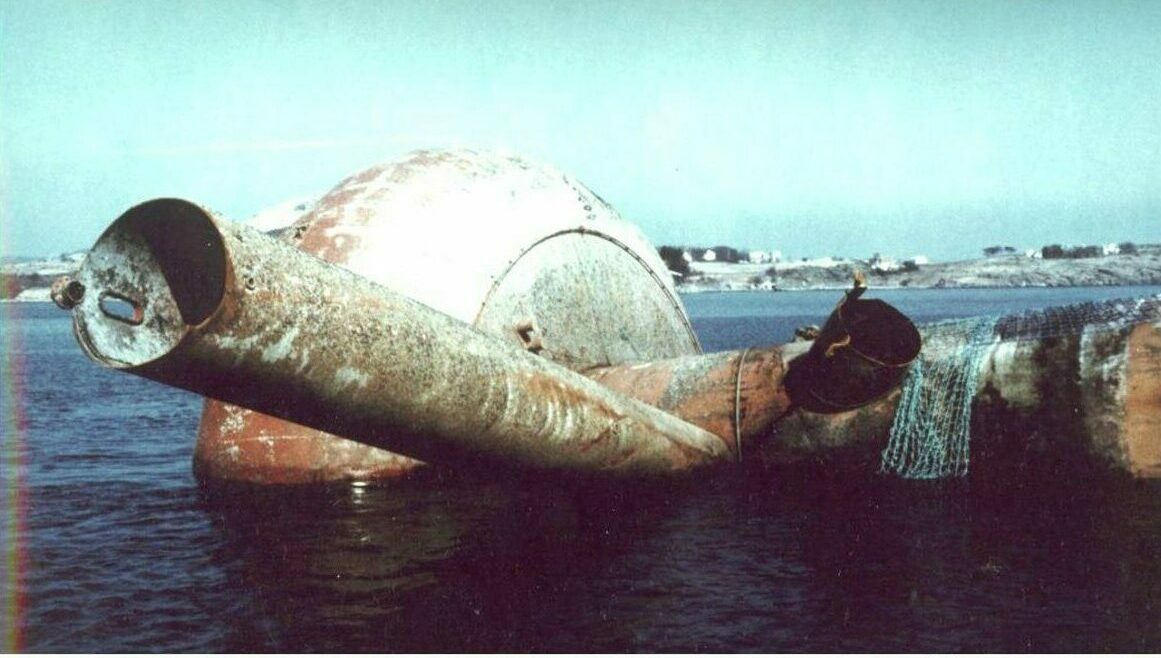

Lian helped inspect the leg, right after it had been towed ashore and was anchored in the Åmøyfjord in Stavanger. Until October of 1980, he was exempted from his usual duties at Statoil to work exclusively on the Kielland accident. This was done in Statoil’s materials laboratory with help from the materials engineering department at Forus in Stavanger.

His report was finished on 30 September 1980, while the Commission of Inquiry’s report was published in the spring of 1981.

Lian recognizes the pieces of metal in the box and confirms that they come from Kielland. The cause of the accident was a bad weld around a hydrophone mount.[REMOVE]Fotnote: A hydrophone is a listening instrument that was used to be able to position the rig in relation to the borehole. A crack developed over time. Most of the metal pieces are samples from the fracture surfaces of the torn D-leg. It turns out that these are parts of the hydrophone mount.

Hydrophone mount:

The hydrophone mount and fracture surfaces were carefully examined. Samples were cut and sent toanalysis at several locations. All the tests yielded the same result: the metal was up to the current standards.

Lian says that larger samples were cut with a welding torch. Small metal samples were sawed off.

Metal samples

The pieces were numbered. Which leads Lian to believe that the pieces are from the same area.

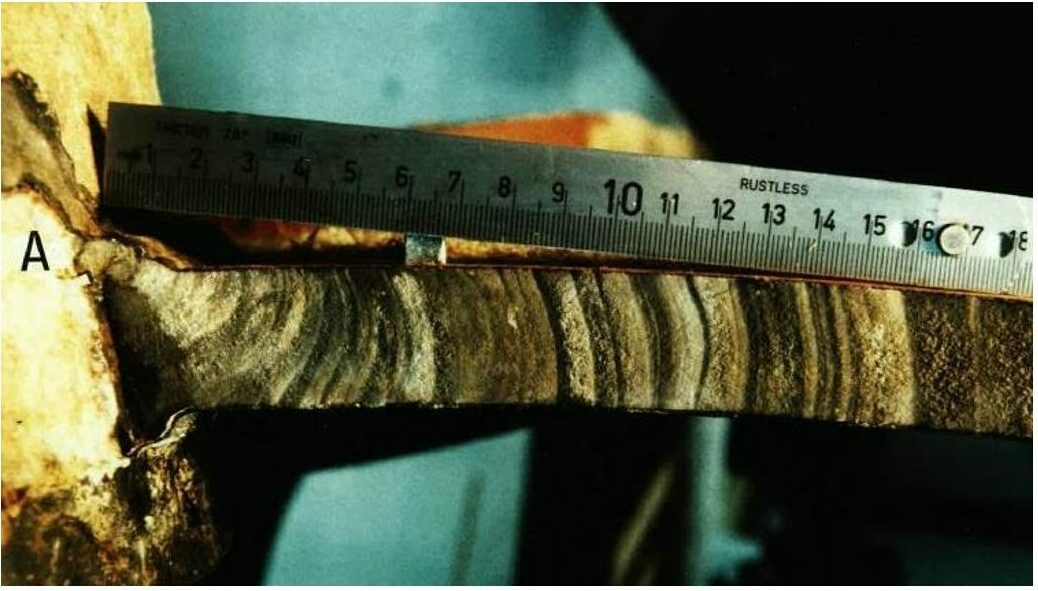

The gradual development of the cracks meant that the fracture surfaces formed a pattern akin to the growth rings on a tree. This is typical for fatigue failure and indicates gradual devlopment. The lines are not very visible in the samples. The pieces were treated in order to make the stress lines more visible. The photo below was taken by Lian in connection with the investigations in 1980.

Lian says that by examining the stress lines, it is possible to determine where the pieces fit together.

The box probably also contains pieces of the weld where the fatal crack occurred. Lian believes that pieces of metal with museum identifer NOMG-00802 and above (see photo below) may originate from where the area around the weld on the hydrophone. The samples are encased in plastic. It was done to be able to see the structure of the metal better.

References:

Gunnleiv Hadland. Innflytting i nytt magasin. Norwegian Oil Museum. Yearbook 2020.

Interview with Bjørn Lian in the Memory Bank. Vi som bestemte støttet og var til stede. Available from: https://ebooks.uis.no/plugins/generic/pdfJsViewer/pdf.js/web/viewer.html?file=/index.php/USPS/catalog/download/11/8/29/?inline=1#page=36

Bjørn Lian. Ulykken med Alexander L. Kielland, Materialtekniske undersøkelser utført av Bjørn Lian i Statoils materiallaboratorium.31. mars-30 september 1980. Available in the Digital Archives here: https://media.digitalarkivet.no/view/90960/459

Norwegian Official Reports:1981:11. The “Alexander L. Kielland” accident. Available in the Digital Archives here: https://media.digitalarkivet.no/view/112047/189

Further reading:

Report on work in the Åmøyfjord and Lian’s first day at work for the Commission of Inquiry. Available in the Digital Archives here: https://media.digitalarkivet.no/view/105514/548

Accident investigation “Alexander L. Kielland” Investigation of fracture surfaces and materials. Available in the Digital Archives here: https://media.digitalarkivet.no/view/105531/46

arrow_backSurvivors and bereaved in UK.Successful Kielland gatheringarrow_forward